YOUR PARTNER FOR IoT & INDUSTRIE 4.0 SOLUTIONS

ABOUT US

We are a medium-sized software company with the constant drive to find the best individual solution for our customers. With passion for technology, details and our customer contact, we face current and future challenges.

Already 30 years ago we dealt with remote meter reading in the energy sector at various municipal utilities. In 2004, the Franke & Werner GmbH was created in order to advance the business field of the remote transmission of consumption data further. Already then, we were thinking about the future and developed telemetry solutions for data-driven machine management for coffee and vending machines which is now referred to as “smart vending”.

In addition, we support the implementation of smart metering projects, i.e. the measurement, determination and control of energy consumption for smart networked meters in Germany and Austria. Using technologies such as smart data analysis or cloud services we develop measurement solutions for industry 4.0 and the Internet of Things.

Thus, the topic M2M (Machine-to-Machine) communication forms our central core competence. We offer individual implementations of the automated exchange of information between terminal devices to our customers, such as measuring devices, machines or with a central control centre (cloud).

For example, using appropriate communication channels, remote monitoring, control and maintenance of machines, plants and systems, is possible. We discuss with our customers and partners which hardware or type of communication is or should be used. We will also be happy to advise you in this respect. It is not only important for us to find a solution for future devices and machines, but also to integrate those which are already in use and/or in an existing device architecture.

Our previous solutions are used worldwide with more than 100,000 productive systems.

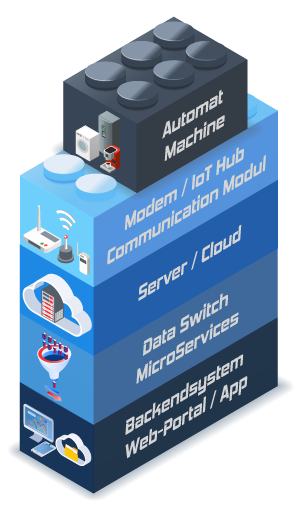

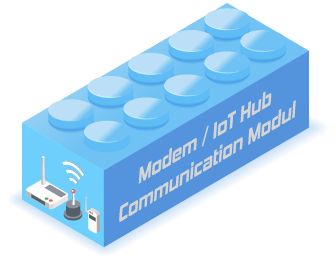

OUR BRICKS FOR YOUR SOLUTION

Industry 4.0 – from your machine, your automatic unit to an individualized app, a portal or the way to your existing backend system – by consulting us, you get the missing “bricks“ or the complete solution from a single source. We adapt the hardware and software modules to your use case and guarantee your desired IoT result. If you only need single modules, e.g. if you have your own cloud, your machine already has a communication unit, or you have the pure need for a data switch or appropriate micro services, we are also available to you as a competent partner in these cases.

YOUR USE CASE – DATA COLLECTION

Your machine, your automatic unit or your individual use case, which you would like to connect digitally and remotely, is the central starting point in focus. In the best case, your machine, your automatic unit already has an interface and offers the option of tapping or recording the data generated on the machine. Possible interfaces could be e.g. an Ethernet, USB, COM interface or various BUS systems (e.g. Modbus, EEBus) through which the machine can be accessed. Insofar as the data has not yet been recorded digitally, e.g. the fill level of a gas tank or the temperature of a component, we offer you our technical know-how and try to create a suitable solution and communication path for you. Our core competence is to find innovative and technically functional solutions for your sensors and actuators.

We have already dealt with the following industries and use cases.

THE COMMUNICATION LEVEL

Depending on the use case, area of application and your individual requirements, we conceive the design for the ideal communication level together with you.

In case if your machine does not yet have a communication module to transmit your machine data remotely or to receive data from an established server, we will assist with our many years of expertise and with our partner network of industrial pc / mini pc and modem manufacturers.

We have been working with hardware partners for many years and therefore we always have the current overview of technical options for transmitting data via m2m (machine to machine) communication.

Your use case, your preferences and the technically available options determine whether the communication creates a wired (network module) or wireless (cellular modem) interface to the Internet.

Communication always takes place via secure connections and we also act as partner of large communication providers, with whose SIM cards also secure networks can be set up. When designing your solution, the sensitivity of your data is always considered. We will coordinate together to determine which security level must be achieved.

The connections can be established directionally and bidirectionally, so that not only data can be called up from the machine, but also updates can be imported into the machine.

For us, the intelligence of data processing does not belong in the communication structure. It acts purely as a transmission medium. All further processing steps take place on the following server level.

SERVER PROVISION / HOSTING

At first, the captured data is transmitted to a secured server, also known as cloud, via the communication level. Subsequently, it is kept there.

We can host your infrastructure for you by cooperating with experienced and certified hosting partners. We take care of the provision of the hardware as well as the maintenance and operation of the systems including databases.

If you already host a cloud or your own server, there is also the possibility to use this infrastructure, provided the relevant basics are met.

The server and the central data storage provide the basis for displaying, preparing or further processing the captured data. Nevertheless, the opposite communication to the communication units and to the machines is set up via the server to bundle from there or to carry out individual parameterizations.

DATA PROCESSING – SERVICES

The brick of services includes what happens to the data captured and transferred to the server. These so-called micro services can cover a wide variety of use cases and can be standardised as well as completely customized.

At first, the captured data is prepared and filtered. Pure machine language does not necessarily have to be a finally readable data format. Our services can thus act as a translation or converter.

The decisive factor is how and where the respective data is required for editing, further processing or processing. Web portals, apps and back-end systems (ERP systems) are customary in the market in which the corresponding evaluations can then be displayed and carried out. In this connection not everyone speaks the same language. With our services, we offer you a corresponding data switch and implement the necessary interfaces so that your data ends up where you want it. We prepare your data for individual interfaces or for the industry-specific standard interfaces.

Moreover, the data obtained can be interesting for different users. Using the example of an industrial coffee machine, there are three different parties interested in the machine’s data. Firstly, the manufacturer (is interested in maintenance-relevant data), the machine operator (is interested in consumption data, fill levels, recipes, etc.) and the end user (is interested in his consumption data, product recipes). The respective data can be redistributed with our services via a data switch so that every interested party only receives the data that is relevant or permitted for them.

DISPLAYING YOUR DATA

No matter whether an existing / individual app, your own or cross-manufacturer web portal, the transfer to your existing backend system(s) or the sending of a rotational status report… We ensure that you receive the required output of your data and can make necessary entries.

Together with a network of appropriate partners, you can benefit from a wide range of output options.

REFERENCES

Networked vending machines

Our networked vending solution allows you to monitor your vending machine usage, remotely adjust machine settings and efficiently plan maintenance.

Bidirectional communication between the coffee vending machines and a central host system takes place via edge gateways that exactly fit into the vending machines. All defined data is collected via this connection and the gateways send the determined data to a central server (cloud) via mobile communications. From there, the data is processed as a website in a clearly arranged and individually designed data cockpit.

It is also possible to import firmware updates remotely or to transfer settings such as prices and recipes to the coffee dispenser.

- Simple networking and evaluation of your distributed vending machines

- Use new business models, e.g. pay-per-use

- Ideal service and maintenance intervals through monitoring of current usage data

- Cost savings and better quality management

- Flexibly configurable user interface and reports

The following video shows our already implemented expertise in coffee vending machines:

CONTACT

Are you looking for the right telemetry solution for your vending machines and coffee dispensers?

Would you like to collect data from other machines, vending machines, systems or measuring equipment by remote reading or adjust parameters remotely?

Contact us. We look forward to hearing from you!